| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : PFT

Model Number : OEM

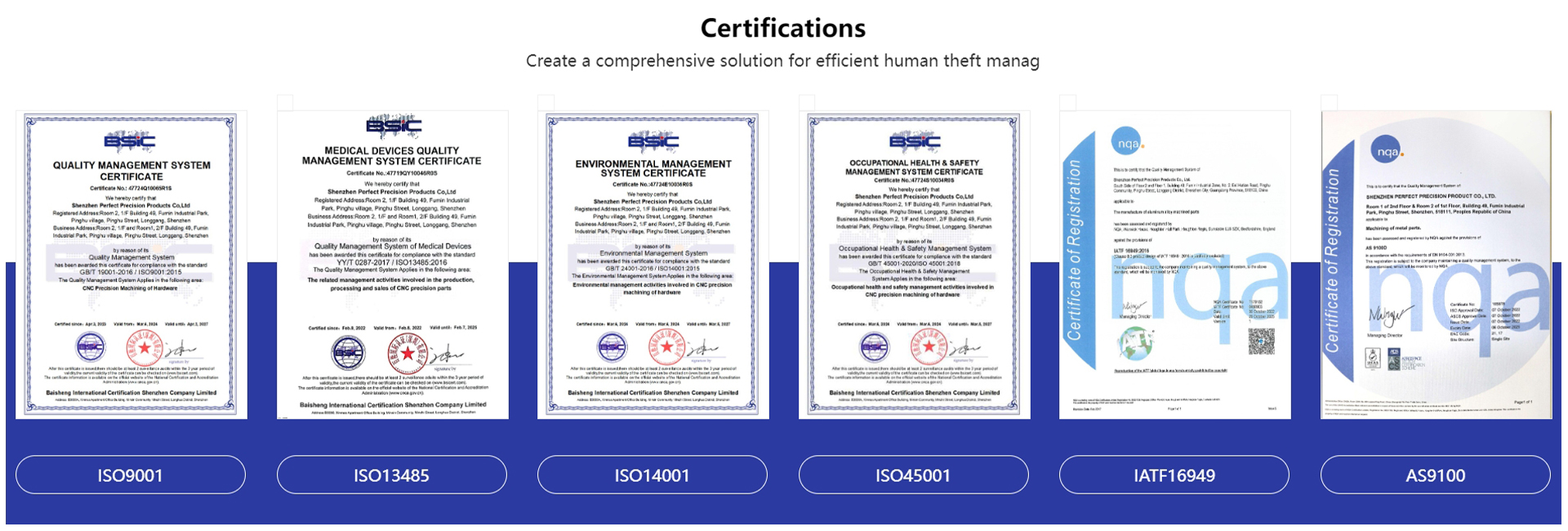

Certification : ISO9001:2015, ISO13485:2016

Place of Origin : Guangdong, China

MOQ : 1PC

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10000Pcs/ Month

Delivery Time : 7-15 work days

Packaging Details : As the requirement of customer

Keyword : Injection Molding Accessories

Material : ABS

Application : Any

Size : Custom size

Service : OEM/ODM

Plastic modling type : Injection

Shaping Mode : injection mould

Surface Treatment : Wire Drawing And Polished Smooth

Production Process : Injection Molding

Color : Customized

Mold Application : For molding electronic products

Forming Way : Plastic Injection Molding

Injection Molding Machine : 100Ton

Quantity : Small to large scale production

Ejection : Automatic Pulp Ejection System

Part Color : Grey (Custom made accordingly)

Qc Report : QC report attach

When it comes to modern manufacturing, precision matters. Whether you're in the automotive industry, electronics, or consumer goods, getting the right plastic parts can make or break a product. One of the key processes behind many of today’s high-quality plastic components is injection molding—and when combined with custom ABS gears and accessories, the result is durable, accurate, and highly repeatable parts.

What Are Precision Plastic Accessories?

Precision plastic accessories are small parts made from plastic that require tight tolerances and consistent quality. These could be anything from clips and fasteners to casings, spacers, or detailed fittings used in machinery or devices.

Why Injection Molding?

Injection molding is the go-to process for producing plastic components at scale. Here’s why it’s so widely used:

If you need hundreds of custom plastic accessories that all perform the same way, injection molding is the method that makes it possible.

The Power of Custom ABS Gears

ABS (Acrylonitrile Butadiene Styrene) is a popular thermoplastic known for its strength, rigidity, and impact resistance. It’s used in everything from LEGO bricks to automotive components.

When it comes to custom gears, ABS is often a top choice for several reasons:

Whether you're prototyping a new mechanism or replacing a worn-out gear in an existing machine, custom ABS gears offer a reliable and cost-effective solution.

The Bottom Line

Injection molding is the workhorse of mass manufacturing for a reason. It’s fast, consistent, and incredibly efficient at producing high-quality, precision plastic parts like custom ABS gears.

1. Are you a manufacturer or a trading company?

|

|

Precision Plastic Accessories, Injection Molding, Custom ABS Gear Images |