| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : PFT

Model Number : OEM

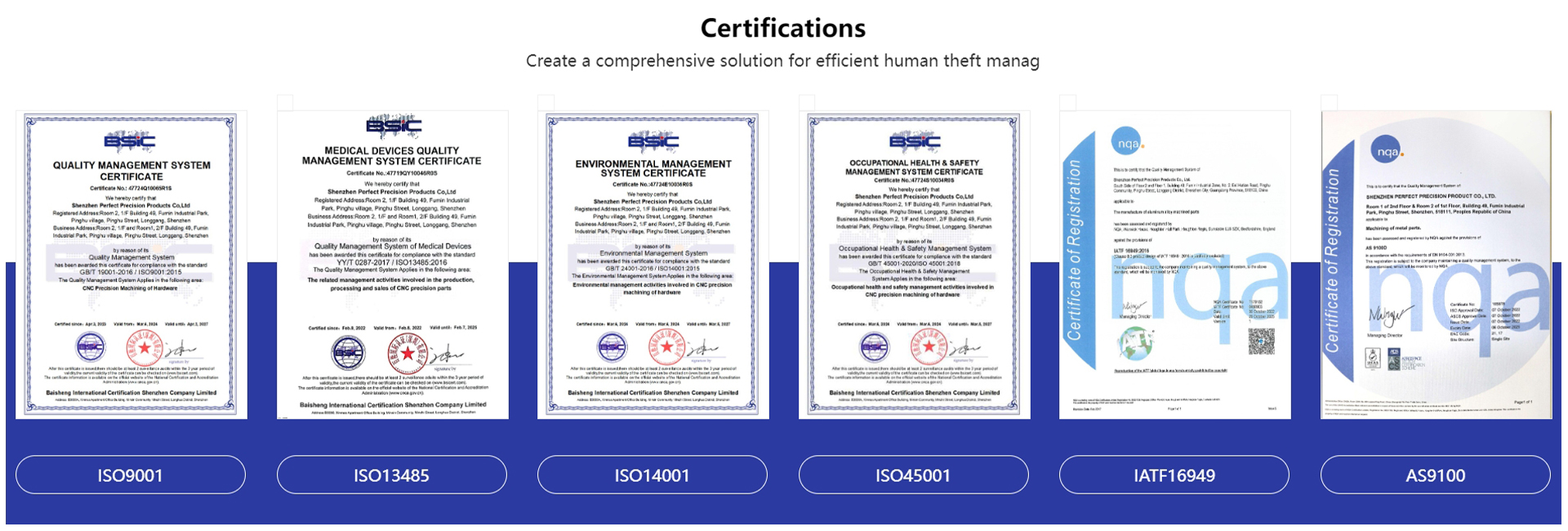

Certification : ISO9001:2015, ISO13485:2016

Place of Origin : Guangdong, China

MOQ : 1PC

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10000Pcs/ Month

Delivery Time : 7-15 work days

Packaging Details : As the requirement of custome

Plastic modling type : Injection

Color : green

Product name : Custom Transparent ABS Plastic Injection Molding Plastic Parts

Size : Custom size

Material : ABS,PA,Nylon

Process : CNC machining

Service : Customized OEM\CNC Machining Service,

Quality Control : ISO9001:2015 certificated

Quantity : Small to large scale production

Texture : As Per Customer's request

Surface Finish : Polishing

Surface Finish Process : heat treatment

Business Type : OEM manufacturer

Inspection Report : available

Silkscreen : Accepted

Grinding Precision : 0.002mm

Product Color : Grained surface decoration (Custom made)

In the rapidly evolving electronics industry, the demand for components that are both compact and efficient has led to the adoption of advanced manufacturing techniques. CNC (Computer Numerical Control) injection molding has emerged as a pivotal process in producing electronic molds, offering precision, versatility, and scalability.

Understanding CNC Injection Molding in Electronics

CNC injection molding combines the precision of CNC machining with the efficiency of injection molding. This process involves injecting molten material into a mold cavity under high pressure, allowing for the creation of intricate and detailed electronic components. The integration of CNC technology ensures that molds are crafted with exacting tolerances, which is crucial for the functionality of electronic parts.

Benefits of CNC Injection Molding for Electronic Molds

Applications in Electronic Component Manufacturing

CNC injection molding is instrumental in producing various electronic components, including:

Conclusion

Integrating CNC injection molding into the production of electronic molds addresses the industry's need for precision, complexity, and efficiency. By partnering with experienced manufacturers, businesses can achieve high-quality electronic components that meet the stringent demands of modern technology.

1. Are you a manufacturer or a trading company?

|

|

CNC injection molding electronic mold Images |